Introduction

In a world that never stops advancing, the construction industry leads the way as a pioneer in innovation and transformation. With each passing day, modern construction methods and advanced techniques pave their way toward a future that was once unimaginable. From innovative prefabrication techniques to stunning advances in 3D printing, and from collaborative Building Information Modeling (BIM) systems to virtual reality experiences, the construction industry is witnessing remarkable transformation. The main point of this article is to explore and discuss the impact of modern construction methods and techniques on the construction industry. It highlights various developments such as prefabrication, 3D printing, Building Information Modeling (BIM), and virtual reality, emphasizing how these innovations are transforming construction practices and improving efficiency, sustainability, collaboration, and ultimately reshaping how buildings are designed and constructed.

1. Prefabrication and Modular Construction

Prefabrication is the process of manufacturing building structural elements in advance at an off-site location, then transporting and assembling them at the construction site. This innovative and popular approach in the construction industry is an effective response to challenges of time, labor costs, and environmental sustainability.

Key Benefits of Prefabrication:

Increased Speed and Productivity

Prefabrication allows for reduced construction time as structural elements are prepared in advance with precision in manufacturing facilities. This helps reduce construction duration and increase delivery speed.

Improved Construction Quality

Prefabrication provides the factory with an opportunity to achieve high quality control, where strict standards are set and adhered to in the manufacturing facility. Advanced technologies and high standards are used to ensure element quality and precise preparation before transport.

Reduced Waste and Environmental Pollution

Prefabrication reduces the amount of materials used at the construction site and resulting waste. Consequently, it reduces environmental pollution and negative impacts on the environment surrounding the construction site.

Enhanced Sustainability

Prefabrication is considered a sustainability technique that promotes efficient use of energy and resources. Thus, it contributes to reducing carbon emissions and the overall environmental footprint of the construction process.

Key Developments in Modular Construction:

Although modular construction is often confused with prefabricated buildings, they are not the same thing. In fact, modular construction is a category of prefabricated construction. Modular construction involves building complete sections of the project before shipping those pieces to the site. This includes plumbing, electrical, and everything the functional unit needs.

Advanced Production Systems

New developments in production systems facilitate manufacturing and assembly processes of structural elements. These developments include the use of modern technology such as robotics and automation to increase efficiency and reduce errors.

Use of Advanced Materials

Advanced high-performance materials are used in modular construction to improve the quality and performance of structural elements. These materials include high-performance concrete, reinforced fibers, composite panels, and tempered glass.

Digital Technology

Use of virtual reality techniques and Building Information Modeling enhances successful implementation of modular construction. These technologies enable engineers, contractors, and clients to interact with building design, analyze it, and provide feedback before actual construction begins.

These developments and current studies highlight that modular construction represents a promising approach in the construction industry, achieving tremendous improvements in construction speed, quality, and sustainability. Despite challenges of modular construction, the significant benefits it offers are driving the industry toward adopting this innovative approach in the near future.

2. 3D Printing in Construction

3D printing is one of the innovative modern technologies that allows production of three-dimensional objects in layers built upon each other, using a 3D printer. Digital designs are converted into special printer definition files (such as STL files), and the printer uses these files to guide the printing process and create three-dimensional objects.

Advantages and Applications in Construction Industry:

3D printing in the construction industry offers many important advantages:

Design Freedom

Allows engineers and designers the ability to create complex structures and precise design details that are difficult to achieve with traditional construction techniques.

Waste Reduction

3D printing can be used to produce precise parts with high accuracy, reducing waste associated with materials and resulting costs.

Customization Capability

3D printing allows design and production of parts according to specific individual needs, contributing to achieving customization and meeting customer requirements better.

Fast Construction

Construction time can be significantly reduced using 3D printing technology, where structures are built layer by layer automatically and with the possibility of operating without constant monitoring.

Challenges and Future Potential:

Despite clear advantages of 3D printing, there are still many challenges facing it in the construction industry, such as load-bearing strength and sustainability, and costs of materials used. However, researchers and engineers continue to improve this technology and face future challenges.

Material Resistance and Load-Bearing Strength

Achieving required load-bearing strength and durability for three-dimensional construction structures is a major challenge, as materials used in 3D printing need to meet engineering requirements to ensure necessary durability and sustainability for construction.

Material and Environmental Sustainability

3D printing technology requires use of materials such as plastic and resins, which may raise concerns about material sustainability and environmental impact. Development of environmentally friendly and biodegradable materials for 3D printing must be considered in the future.

Material and Operation Costs

3D printing technology is still in the process of continuous development and improvement, and costs of some materials and printing techniques may be high at present.

Safety Instructions and Standards

3D printing operations require special care and attention in terms of safety. Specific safety guidelines and standards must be implemented to maintain worker safety and ensure smooth and successful construction operations.

The diverse uses and benefits of 3D printing in the construction industry show that it plays an important role in improving and transforming the construction industry. 3D printing has enabled us to design and build complex structures with high accuracy and efficiency, providing many opportunities for innovation in design and construction. 3D printing has long been considered an innovative and futuristic tool that contributes to developing the construction industry through enabling customized design and improving efficiency and sustainability if widely adopted and used.

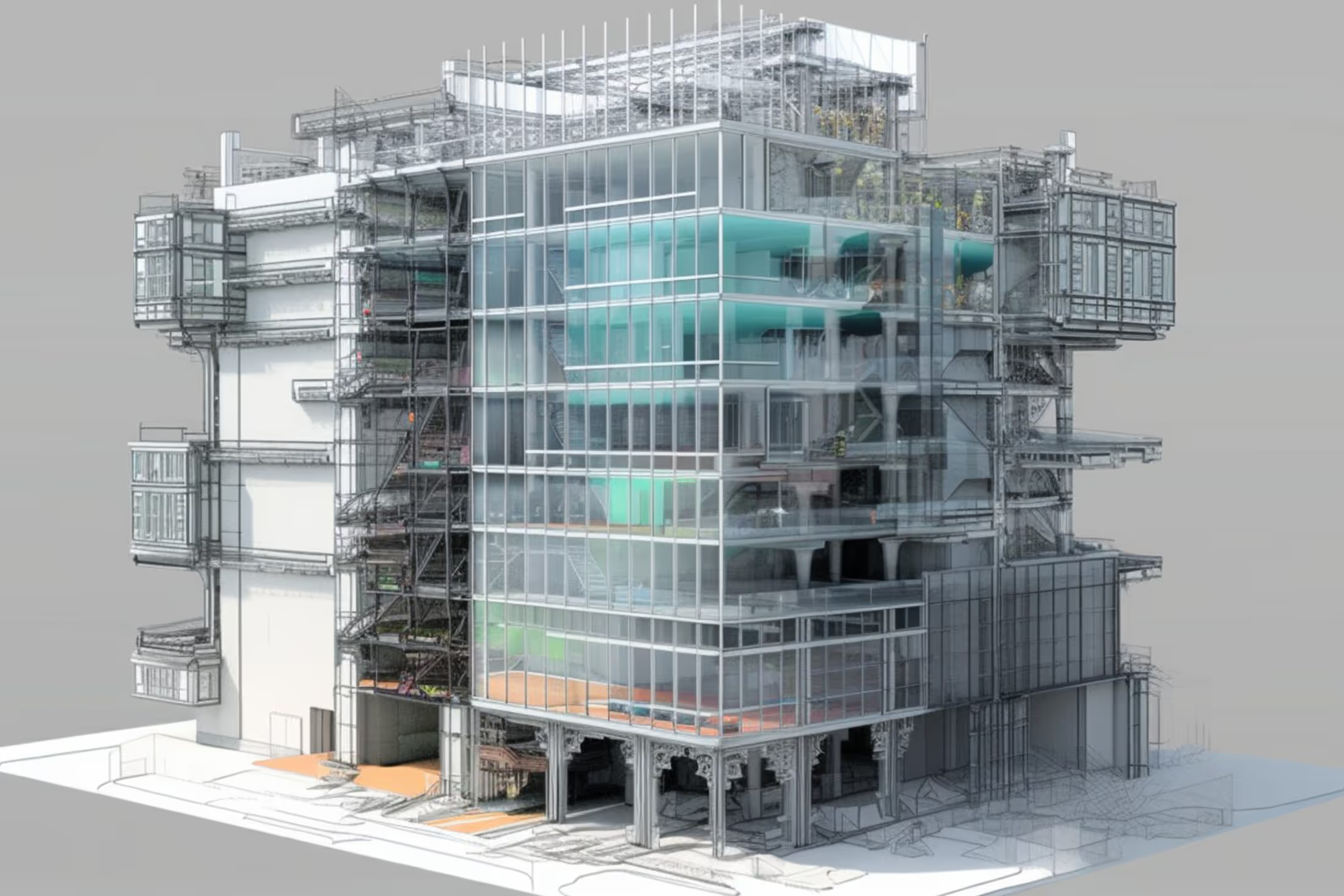

3. Building Information Modeling (BIM)

Building Information Modeling (BIM) is an intelligent process based on a 3D model that provides engineers of all specializations and stakeholders with information about physical, chemical, and mechanical properties of all project elements. The model also includes detailed information about materials, dimensions, systems, and other components in the project.

Building Information Modeling (BIM) is considered a technology based on using software and digital tools to create three-dimensional models representing various information and components of a construction project. BIM provides a comprehensive and integrated view of the project, where engineering, architectural, design, structural works, equipment, and materials information are integrated into one model that is updated simultaneously. BIM principles are based on collaboration and information sharing among all stakeholders involved in a construction project, including architects, structural engineers, building contractors, and owners. Collaboration and communication are improved at all stages of the project life through use of BIM techniques.

Enhancing Collaboration and Communication in Construction:

BIM processes contribute to enhancing collaboration and communication in the construction industry through several aspects. First, the three-dimensional virtual model includes comprehensive information about the project, allowing participating members clear understanding of important details. Additionally, all members can update information in real-time, meaning teams have the same updated data and can work together. Furthermore, BIM techniques can be used to simplify and accelerate operational processes such as design, construction, documentation, and cost control. This means effective coordination and integration can be achieved among all concerned parties, reducing errors and discrepancies and enhancing overall project efficiency.

BIM for Facility Management and Building Maintenance:

BIM is viewed as an auxiliary tool for creating an integrated database that includes engineering information, building components and details, and equipment and facility systems. BIM models provide comprehensive information for maintenance management, achieving better efficiency in facility management operations and maintenance plans. Facility management and building maintenance are important aspects of project life that must be considered after construction operations are completed.

Information Documentation

BIM documents all necessary details and information for facility management and building maintenance. Facility, equipment, material data, and operational requirements are included in the three-dimensional model, facilitating easy access to and updating of this information.

Maintenance Management

BIM can be integrated with existing maintenance management software to provide a comprehensive platform for managing operations and proactive maintenance planning. BIM allows setting a specific maintenance schedule and assigning periodic maintenance tasks based on reliable building information.

Performance Monitoring and Continuous Improvement

BIM provides opportunity to monitor building and facility performance over time. Performance information can be recorded based on real data and used to analyze performance and enhance strategic maintenance decisions and improve building efficiency.

Time and Cost Savings

BIM works to improve resource use and better maintenance planning, reducing unscheduled maintenance costs and contributing to time savings.

Enhancing Communication and Collaboration

BIM allows communication and collaboration among all parties involved in facility management and building maintenance operations. Participants can access the same information and collaborate in real-time to make correct decisions.

Thus we see that Building Information Modeling (BIM) is an innovative and powerful technology that contributes significantly to improving and transforming the construction industry. It provides comprehensive documentation of information, effective monitoring of building performance, and gathering important information in a comprehensive model, establishing a solid foundation for achieving efficiency and continuous improvement in building performance and maintenance procedures. Using BIM, construction processes and facility management can be improved and the construction industry transformed to a new stage of integration and efficiency. Using BIM can lead to time and resource savings, error reduction, improved space utilization, and achieving highest quality levels in construction.

4. Virtual Reality and Augmented Reality in Construction

Technology transformation and innovation in various fields have led to emergence of new concepts that contribute to improving the construction industry. Among these new concepts are Virtual Reality (VR) and Augmented Reality (AR), which are promising fields that align with the aspirations and needs of the construction industry.

Key Applications:

Project Visualization

Virtual reality is primarily used in the construction industry to visualize the project before actual construction begins. Engineers and designers can use specialized devices and software to create three-dimensional models reflecting project details, allowing teams involved in the project better understanding of the project and verification of meeting required conditions and requirements.

Safety Improvement Through Virtual Training

Augmented reality enhances safety in the construction industry through use of virtual training, where project workers can use augmented reality glasses to experience various educational and training scenarios they may face in the workplace. Thanks to this technology, workers can train on correct safety procedures and follow required instructions without need for hazardous equipment and materials.

Real-Time Project Monitoring

Virtual technologies also play an important role in monitoring and following up on construction projects in real-time. Supervisors and supervision teams can use virtual reality special devices for direct communication and sharing project information in real-time. They can access plans, drawings, and architectural updates immediately, facilitating decision-making and procedure organization.

Live Virtual Instructions

Augmented reality can be used to provide live instructions to workers during project execution, by displaying instructions and directions on augmented reality screens.

Benefits for the Industry:

The construction industry is rich with many challenges that can be overcome through use of virtual and augmented technologies. These technologies provide opportunities to reduce errors and costs, increase work safety, and improve communication and coordination between work teams. Full utilization of these technologies is pivotal for developing the construction industry and achieving higher productivity and quality.

Through full utilization of these technological innovations, many benefits can be achieved in the construction industry. These benefits include improving design quality and reducing errors and costs, enhancing work safety and reducing risks, and improving communication and coordination between different work teams. If virtual reality and augmented reality are used correctly and effectively, they can enhance transformation and innovation in the construction industry. Use of these technologies can be expanded to include more areas such as education, training, design, and marketing. In general, virtual reality and augmented reality enhance the construction experience and contribute to achieving better and more accurate results. Utilizing these modern technologies in the construction industry represents an important step toward comprehensively transforming and improving this industry. Ultimately, virtual and augmented technologies can be one of the main tools in achieving digital transformation in the construction industry. Through continuing investment in these technologies and expanding their scope of use, competitiveness can be enhanced.

Conclusion

With the spread of technology and modern innovations in the construction industry, this industry has witnessed a real revolution that has transformed from traditional operations to smart and sustainable technology. Construction is no longer just a set of human operations, but has come to rely on innovative uses of predesign, three-dimensional printing, Building Information Modeling (BIM), and virtual reality. These technologies have brought about a radical transformation in the construction industry, leading to increased efficiency and significantly improved results. Looking at the uses of these innovative technologies, the construction industry can overcome challenges related to resource shortages, time, and high costs. When prefabrication and three-dimensional printing are used, entire construction processes are transformed into advanced technological operations that allow faster, more efficient, and higher quality construction. In addition, Building Information Modeling can provide integrated project management and effective performance tracking, helping to improve coordination and communication between all work parties. Furthermore, this advanced technology has led to enhanced sustainability in the construction industry. By investing the construction industry in these technologies and adopting them widely, we find that transformation and improvement in this sector is not just a dream, but a near reality. Adopting technology and innovations will help achieve continuous improvement in construction efficiency and quality, reduce errors and costs, in addition to enhancing sustainability in construction operations and achieving sustainable growth in this vital industry. In short, if the construction industry wants to remain distinguished and unique in this digital age, it must invest in future technology and adopt advanced innovations. Using this modern technology, construction can overcome all challenges and achieve real transformation in the construction industry through improving productivity, quality, and sustainability.